Amigo Notes

From the instructions:

"BALLAST: The ballast is a lead or iron casting of

approximately 1775 lbs. total. While many amateurs attempt to do their

own casting in lead, the inexperienced person may wish to leave this work

to a foundry. With iron ballast, due to the higher temperatures required,

this is almost a necessity. In either case, a pattern will be required,

and the amateur can make this, using the stations contours for guides to

determine the shape. Several boatbuilding texts, as well as texts

concerning foundry practices related to sand casting, cover the subject

of castings and pattern making in more detail for those with no

experience and who wish to do this task. The ballast is shown on Sheet 4

of 8. The length and configuration of the ballast will vary with the

material, but in both cases, the ballast connects to the bottom of the

keel/stem member and is bolted through it. A total of six bolts minimum

are used through the ballast, one near each end at the centerline, and

two spaced approximately equal distance between these on either side of

the centerline as shown by Det. 'O' on Sheet 8B of 8. Keel bolts

are 1/2" diameter, preferably bronze for lead ballast and galvanized

wrought iron for cast iron ballast. With cast iron, the bolts can be

threaded into the casting at the intermediate positions in lieu of

through bolts. The ballast should be weighed after casting. If the weight

is not up to specifications, then ballast can be added internally in the

hull, preferably after launching with a normal load for trimming

purposes. The weight of the ballast, however, can vary approximately 5%

plus or minus in either case without dire results if there is a

discrepancy in the figure. The top of the ballast should be a firm fit to

the bottom of the keel/stem. This joint should be generously coated with

a flexible sealant compound such as polysulphide polymer or silicone

sealant before tightening up the bolts. Keel through bolts can be

threaded rods with nuts jammed on the lower ends, recessed into the

ballast, and later filled or plugged. Nuts on the inside are fitted with

large flat washers, or at the intermediate bolts, with washer plates

preferably spanning across to pick up both bolts either side of the

centerline. The bolts at either end of the lead keel, and at the aft end

of the iron keel, however, are installed concurrently with the wood keel

appendages noted in the following. Bed all nuts and bolts in sealant or

equivalent material to prevent leaks.

WOOD KEEL APPENDAGE: Wood is used to build up on the bottom of the

keel/stem member fore and aft of the ballast. These appendages fill out

the hull form and can be made from layers of thickness to suit, or solid

stock, built up in place. With the lead keel, the fore and aft end

ballast bolts pass through this appendage, but with the iron ballast,

only the aft bolt passes through the appendage. Use the same sealant at

the junction between the ballast and wood as used on top of the

keel."

Sail dimensions:

Masthead rig- Main - Luff: 24'-0", Leech: 25'-6", Foot: 9'-9", SqFt: 117

- Jib - Luff: 24'-0", Leech: 21'-6", Foot: 10'-6", SqFt: 113

- Genoa - Luff: 26'-0", Leech: 24'-0", Foot: 13'-5", SqFt: 159

- Main - Luff: 14'-0", Leech: 22'-2", Foot: 13'-6", Head: 8'-8", SqFt: 174

- Jib - Luff: 20'-1", Leech: 17'-2", Foot: 8'-11", SqFt: 76

Masthead Rig:

- Mast length: 27'

- Boom length: 10'

Underwater Hardware

- Max. propeller diameter: 12"

- Propeller shaft diameter: 1"

- Propeller shaft length (nominal): 3' 3"

- Stern bearing housing (Fiberglass version): SLC-100L

- Bearing 1" x 1 1/2" for above: 90-354 Bonito

- Stern bearing housing (Wood version): STBO-100

- Bearing 1" x 1 5/8" for above: 90-355 Broadbill

- Shaft stuffing box (Fiberglass version): 90-223 (for 1 3/4" hose)

- Shaft stuffing box (Wood version): SL-100A (for 1 3/4" hose)

460 lbs will sink the Amigo 1"

CLR is located 11' 0"aft of station 10

Masthead Rig CE is located aft of 7' 10" aft of station 10

Gaff Rig CE is located aft of 8' 4" aft of station 10

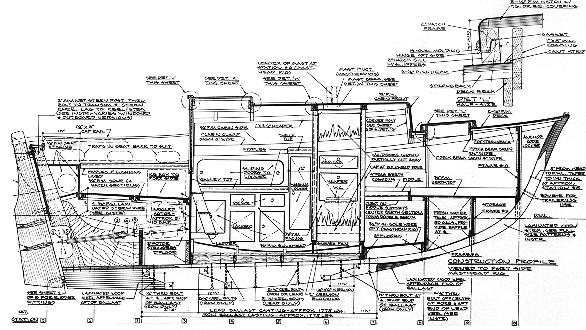

Frame construction, Wood version

FRAME MEMBERS: Contours for the frame members are taken from the full size patterns or loftings. The athwartship frame members vary in their method of construction. The frame at Station #1 is a temporary member that is removed from the hull after righting. This frame is notched at the centerline for the stern knee, or can be made in two halves divided by the stern knee. One way to make this frame is to cut it from plywood and frame it along the edge with solid stock. Other frames are located at Stations #2, #3, #4, #5, #8, #9, and #10, as well as a Bulkhead/Frame ‘A’ between stations #6 and #7. Frame members are not required at Stations #6 and #7, but could be added at either or both stations as temporary frames similar to that at Station #1 if it proves desirable for the planking application. Most of the frame members are shown as laminated members made to the pattern or lofting contours, with or without adjoining bulkhead members. Optionally, these frames could be steam bent members. In other cases, especially where frame contours are relatively straight and are bulkhead units, the frame members can be sawn to shape. In the case of laminated frames, forms to suit the frame contour must be made to hold the laminations in place, using glue and clamps, while the glue sets. Because the frames are symmetrical about the centerline, only one-half of the frame need be formed. After making the laminated portion, the frame can be assembled in the typical manner, with the components shown on Sheet 8B of 8. The strips used in laminating the frames are cut from 1 ¼” nominal stock. Optionally, the frames can be made from 2 ½” nominal or wider stock and the complete laminated member sawn in half forming the two members. The laminations will vary in thickness to suit the noted curvatures, and trial-and-error is the only suitable method to determine the required thickness due to the varying bending qualities of different wood species at varying moisture contents, as well as the differing contours. In making the frames, note that in many cases additional material should be provided outside of the given contour to allow sufficient fairing material for the planking landing. In these cases, the forms used to make the frames will be to the inner frame contours. Also note that any notches in the frames should be to suit the net size of the adjoining member. Points are given on the full size patterns noting the bottom of the keel/stem member. Bulkheads and floor timbers join to the frames as shown, with all such junctions fastened and glued. Floor timbers should be through-bolted with at least two bolts per frame/floor junction, as should side or full width deck beam/frame member junctions. Note that full height bulkheads are not built full height initially in order to clear the building form members. Also note that Frame #9 consists of a partial permanent member and a partial temporary member that can be made similar to the frame at Station #1.