Amp Eater Notes

Shaft drive assembly hardware

From instructions:COMMENT: The following lists the items required for the shaft drive assembly as noted alphabetically on Plansheet 3 of 4. Most parts are available from GLEN-L with the respective part numbers noted. See the GLEN-L On-Line "Inboard Hardware" catalog for prices and more details.

"A" RUDDER: Part No. 90-019. Rudder

size approximately 9" x 9" with 1"

shaft.

"B" RUDDER STUFFING: Part No.

90-102. A Rudder Stuffing Box acts as a bearing and

prevents water from entering the boat around the rudder

shaft. Locate atop blocking #12 so the lower section

protrudes approximately 1/4" below the boat

bottom.

"C" TILLER: Part No. 90-028. A

7" tiller arm is keyed or otherwise held securely to the

rudder shaft. The tiller can be mounted directly atop the

rudder post bracket bearing and act as a collar to hold the

rudder in place. Optional, and better practice, is to use a

safety collar with set screw (GLEN-L Part No. 90-400)

to prevent the Rudder from sliding out.

"D" RUDDER SHAFT SUPPORT: The upper portion

of the rudder shaft must be adequately supported to prevent

side motion. The rudder post shelf, described under #12, can

be made of oak or other hardwood bored to match the rudder

diameter and used as a bearing. However, a commercially

available bronze or nylon bearing is more durable.

"E" STERN BEARING: Part No. 92-700. A

stern bearing is the underwater aft bearing that supports the

prop shaft and bolts to the skeg aft end blocking with

hanger, lag, or through-bolt as shown on the pattern. Counter

bore the aft end blocking as required to fit flush to the

skeg, and the aft end of the PVC tube butts to the stern

bearing casting. The metal sleeved rubber bearing is a

separate item for inserting in the stern bearing casting

(Part No. 93001) for a 1" prop shaft.

"F" PROP SHAFT: Part No. 90-734. The

1" prop shaft is keyed, tapered, and threaded to

accommodate a standard propeller and the opposite end keyed

for the drive pulley. Overall length should be approximately

44", however, take the actual measurement directly from

the work.

"G" PROP NUT KIT: Part No. 90-723.

Lock the prop to the shaft with a key, nut, and cotter

key.

"H" THRUST BEARING: The self aligning thrust

bearing is for a 1" shaft with eccentric (or other)

locking collar. It is bolted to a 2" x 6" x width

to suit member that in turn through-bolts to the Thrust

Blocking #14. See #14 pattern. Position the thrust bearing so

the prop shaft turns freely through it and the stern bearing

; it must spin with the least resistance possible.

"I" STUFFING BOX: Part No. 90-234. A

seal type stuffing gland for a 1" shaft is mounted on

the forward inside end of the PVC shaft tube and coupled to

it with a rubber hose. Trim the tube length to be minimal but

adequate for the rubber coupling hose with two clamps. The

hose is Part No. 90-232 and the clamps Part No.

90-818 (3 required). Leave the hose clamps holding the

stuffing box to the shaft tube loose, install the prop shaft,

rotate it, and allow the hose to adjust the stuffing box for

least resistance; then tighten the two clamps on the shaft

tube and the one on the stuffing box. Grease the stuffing box

bearing through the fitting and recheck the shaft alignment.

It is important that the shaft rotates freely, without

binding, in the stern bearing, stuffing box, and thrust

bearing.

"J" PROPELLER (PROP): The maximum propeller

diameter for the shown skeg and shaft angle is 11" with

the pitch varying with the prop shaft rpm and motor

horsepower. The prototype used an 11" X 12" three

blade prop turning 830 rpm.

The Following is for estimating only. Prices are current as of October 2012. Check on-line Inboard Hardware catalog for current prices.

| Part # | Quan | Price each |

|---|---|---|

| 90-019 | 1 | 275.00 |

| 90-102 | 1 | 106.50 |

| 90-028 | 1 | 43.00 |

| 90-400 | 1 | 11.25 |

| 92-700 | 1 | 163.31 |

| 93-001 | 1 | 81.30 |

| 90-734 | 1 | 175.00 |

| 90-723 | 1 | 5.40 |

| 90-234 | 1 | 35.25 |

| 90-232 | 1 | 12.95 |

| 90-818 | 3 | 6.30 |

| $915.26 | ||

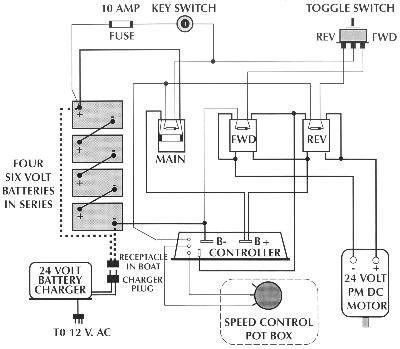

A typical wiring diagram

Note: While this is the wiring diagram for the equipment we used on the Amp Eater, it will not apply to all variations of hardware that can be used. Refer to the literature that comes with the components you use. Do not try to impose this wiring on your components unless it matches the recommendations of your equipment manufacturer. A Curtis pulse modulator controler was used in the above set up.

Electrical components used on the test model

-

Motor: Pacific Scientific, 24 volts DC, 1 hp, 1750

rpm

Cat #BAF 3644-5081-48B, Continuous duty -

Controller: Curtis-PMC #1204-001

24-36 VDC/275 A