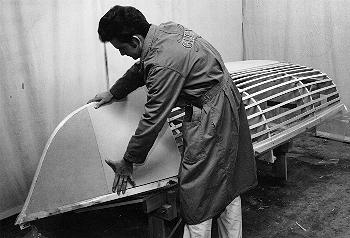

Fig. 7 While the foam panels should fit as closely as possible, small gaps can be easily taken care of by adding scrap pieces of foam. However, mating edges of adjacent panels should be beveled or angled so that the fit is firm. This can be done by trimming with a knife as well as sanding the edge with coarse sandpaper. Along the sheer and keel members, the fit is not quite as critical, because these areas will be beveled along the inside once the form is removed and hull righted. However, well fitted joints are desirable and wide gaps should be avoided.

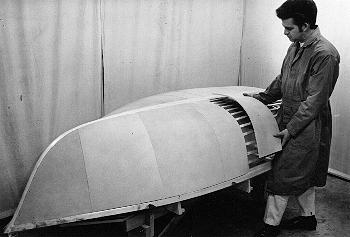

Fig. 8 Where hull contours change rapidly, it may be necessary to use smaller panels laid somewhat on the diagonal, or it may be necessary to heat the panel initially. This small panel was bent to approximate contour and then heated before placement. Panels are fastened from inside the mold with screws or sewn on. In either case, two people, one working inside and other on the outside, are required to get a good application. Continue