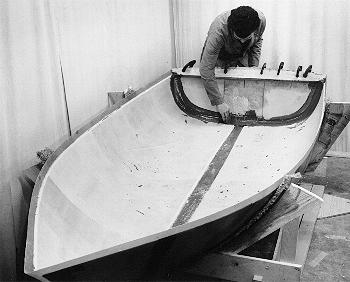

Fig. 19 With the hull righted and the form removed, the interior can be prepared for the inner laminate. Edges of the foam where the hull will have solid fiberglass must be beveled and the corner radiused so the fiberglass materials will not lift and cause air bubbles. This can be done with a knife, rasp, and by sanding. The bare fiberglass surfaces (as along the keel and sheer in the photo) should be sanded and preferably wiped with solvent also in order to assure a positive bond.

Fig. 20 Inside corners such as shown in the photo at the transom area should be fitted with cant strips or a resin putty filler fillet so the fiberglass material will conform to the corner without lifting from the surface. The resin putty filler is made into a trowelable consistency and formed with any circular object such as a plastic lid. Surfacing agent added to the resin or the use of finishing resin will make the filleted area easier to sand. Continue