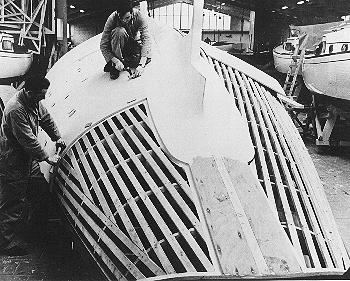

Fig. 25 These workers are using nails fitted with plywood washer blocks to hold the foam in position. Screws are then driven from the underside or the foam sheets can be sewn onto the form members. After this, the nails are removed. Note the solid members along the keel centerline where the foam is omitted. This will be solid fiberglass laminate without any foam.

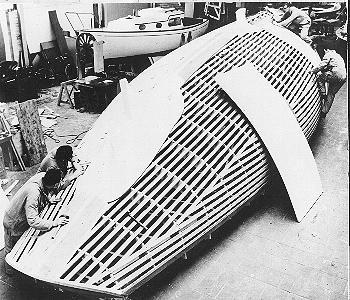

Fig. 26 The sequence in which the foam is applied usually matters little. Here the foam is being applied in relatively large pieces as these can conform readily to the hull contours. Where contours change rapidly, or on smaller boats, the pieces can be cut smaller and/or heated to be flexible. Continue