See Useful Information & Suppliers for source for C-Flex.

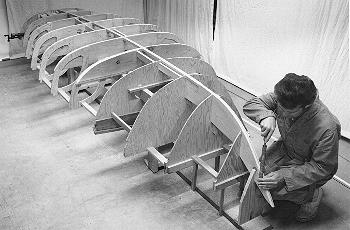

Fig. 1 Several variations may be used to build the form for use with the fiberglass planking method. The photos show a conventional method utilizing transverse molds or forms rather closely spaced, together with a form member for the stem area. The members are erected on a building form, accurately aligned, and braced to prevent movement. The transverse forms must be vertical, at right angles to the centerline, and centered. All members must be level with the set-up level or reference plane. The stem form is beveled on each side of the centerline, however, this may be varied as shown by the details provided.

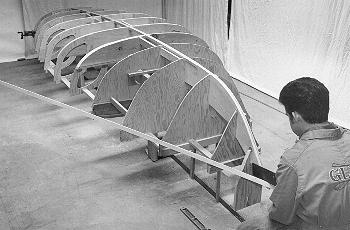

Fig. 2 Battens are usually provided for such areas as the sheer and keel area along the centerline, depending on the design. The ends of the sheer battens are trimmed to mate flush with the side of the stem form. Notches in the various transverse forms are cut to receive the sheer battens which continue to the transom form. In some cases, this sheer batten will remain in the completed hull, in which case, fastenings should not be driven through the members into any of the form structure which will not remain in the completed hull unless they can be removed in some way. Continue