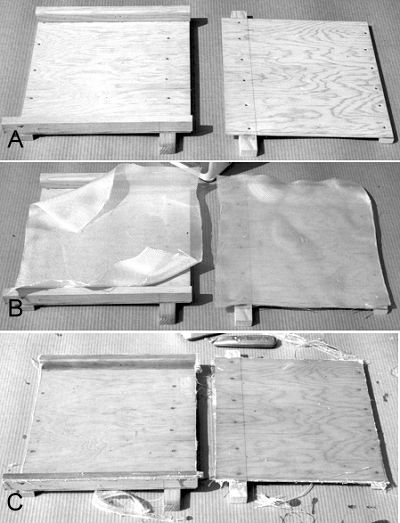

Centerboard and daggerboard trunks are fiberglassed on the inside before assembly. This protects the inside of the trunk from abrasion when the board is raised or lowered and also seals it against water damage. The photos above illustrate the normal procedure.

A Each half is assembled.

B Fiberglass cloth is fitted, then applied.

C The cloth is trimmed and any burrs sanded away.

The final step is to glue the two halves together. We would recommend using thickened epoxy and using a long dowel to form the resin that squeezes out on the inside into a small fillet. If a sailboat is going to leak, it will leak around the board. If the hull is fiberglassed on the outside, we would recommend tucking cloth, as far as practical, into the trunk to protect the exposed edge of plywood.

The hulls shown in the preceeding photos have all been planing powerboats. The procedures are much the same for plywood rowboats or sailboats, but because sailboats tend to have more "rocker" in the bottom, they may look different on the building form. Frames may not all mount directing on the building form. Some may have temporary braces across the frame that will rest on the building form. This will also apply to some powerboats. Other designs may use much abbreviated forms or in some cases, none at all. In all cases, the plans override any differences in the procedures shown.

Return to Plywood Methods

Proceed to Multiple diagonal planking