The Rob Roy as built by

Larry "Rehd" Brown, Fresno, Calif

25 Sep 04:

Last night, I sanded the outer hull again, with 120 grit to get it smooth and

clean, and remove most of the scratches from the coarse paper.. What is left

will cover with the varnish. ( approx. 20 min. )

After washing off the dust and wiping it down I pulled it off the stands and

changed the stands to hold the boat up-right. No time available. This morning I

went out and cut my inner gunnals from the Poplar I bought last year.

In order to get it to bend I had to cut it

down to 1/2" thick by 3/4". I had to do some fancy trimming to get it

to fit into the slots cut in the breasthook, and if I were to do it again... I

think I'd make the adjustments to the breasthook and not the strip. Mostly

because I had to unclamp and unbend it to work on it each time... there are

compound bends here. ( in and out / up and down ) What a pain. :-p Only after I

did the first one did I think of taking a chizel to the inside of that slot and

opening it up a little. Live and learn. My joints didn't turn out as good

as I'd have liked, so I will have to use some thickened epoxy (colored with

the sawdust mix I've used on the rest of the boat) (approx. 2 1/2

hours)

In order to get it to bend I had to cut it

down to 1/2" thick by 3/4". I had to do some fancy trimming to get it

to fit into the slots cut in the breasthook, and if I were to do it again... I

think I'd make the adjustments to the breasthook and not the strip. Mostly

because I had to unclamp and unbend it to work on it each time... there are

compound bends here. ( in and out / up and down ) What a pain. :-p Only after I

did the first one did I think of taking a chizel to the inside of that slot and

opening it up a little. Live and learn. My joints didn't turn out as good

as I'd have liked, so I will have to use some thickened epoxy (colored with

the sawdust mix I've used on the rest of the boat) (approx. 2 1/2

hours)

Got some last minute trimming done on the inner gunnals and mixed up some

Dookie-Schmutz (epoxy and saw-dust/micro-balloons) and started smearing it all

over the place. Well, mostly on the gunnal and inside lip of the  canoe... but I managed to drip it on the canoe

and the workbench?? I spread it thin on the strip and then went to the boat and

applied it to the inner lip on one side. Then, with the excess I went back to

the strip, which had soaked up a good part of the first layer, and applied the

remaining mix.

canoe... but I managed to drip it on the canoe

and the workbench?? I spread it thin on the strip and then went to the boat and

applied it to the inner lip on one side. Then, with the excess I went back to

the strip, which had soaked up a good part of the first layer, and applied the

remaining mix.

I found that an old tooth brush worked exceptionally well for this. And I fould

out over the past months that I wasn't working on the boat that I

didn't have to toss my brushes away every time. I used Plain White Vinegar

and it cleans up the epoxy on brushes very well. As long as you don't let

it start to kick off while on the brush. So, I did the whole job with one brush

and it's cleaned and ready to go on the next application.

I went to the boat and stuck the strip into one breasthook and clamped it

there. Then went to the other end, bent the strip and stuck it in that

breast-hook. Moved over to the center and clamped it in the middle, making sure

that I had an equal amount of bow on each side. Then, just worked along the

side of the canoe and clamped it all down. When I got towards the ends, I had

to remove that clamp and allow the bow to come out of the strip and it slid

further into place. Do to my error I had about 1/167quot; gap at all four ends

:( Supposed to be a snug fit! So, I will have to use some Real Thick

Dookie-Schmutz to fill the gaps and sand it to flush. Calculating that bend

wasn't as easy as I figured. Plus, I spent some time unclamping and

reclamping to get it all relatively even. I repeated the process for the other

side and now that job is completed until final sanding and Varnish application.

One other thing I noticed while doing the inner strips was that it showed how

uneven my sides were, mostly in the center. Possibly do to over sanding when I

was trying to get my joints even and smooth. Bending the Poplar along the edge

gave me a more true line around the side of the boat, so when I get the clamps

off on Monday (I want to wait two days, just for insurance sake, as there's

a lot of torque on those strips) I will run the block plane around the edges

and get them even. (approx. 1hr. 20min.) Now it's time for dinner. :)

While the inner gunnals are curing I decided

to play with the seat, as it's the last thing that goes on, after the outer

gunnals and before varnishing. I cut some scrap 6oz. cloth that a friend gave

me. Layed it out for a little over hang ( bottom side ) all around and wet it

out. I set it aside on some waxed paper to cure. Then, I decided to add some

other seats that were given to me by a boat builder friend. I want to add them

towards the ends of the boat, one low and the other a few inches higher. I cut

out the low seat and got it approx. where I want it, but have to taper the

ends. When I add the third seat, at the other end. I will place it farther from

that end and a couple inches higher.

While the inner gunnals are curing I decided

to play with the seat, as it's the last thing that goes on, after the outer

gunnals and before varnishing. I cut some scrap 6oz. cloth that a friend gave

me. Layed it out for a little over hang ( bottom side ) all around and wet it

out. I set it aside on some waxed paper to cure. Then, I decided to add some

other seats that were given to me by a boat builder friend. I want to add them

towards the ends of the boat, one low and the other a few inches higher. I cut

out the low seat and got it approx. where I want it, but have to taper the

ends. When I add the third seat, at the other end. I will place it farther from

that end and a couple inches higher.  That, I

hope will give some variety to seat placement for different size single

paddlers and offer seats for 3 people in that case. I have 5 grand kids that

this boat is being built for and each weighs in less that 75 lbs. so 3 or even

4 of them would probably fit in there after they aquire some experience. Other

wise it will be myself and one or two of them. These extra seats will be

Velcro'd in and possibly made a little more adjustable with added velcro in

different areas of the hull. Or, left out completely if need be. Man, this

thing is going to weigh a ton. (approx. 1 hr.)

That, I

hope will give some variety to seat placement for different size single

paddlers and offer seats for 3 people in that case. I have 5 grand kids that

this boat is being built for and each weighs in less that 75 lbs. so 3 or even

4 of them would probably fit in there after they aquire some experience. Other

wise it will be myself and one or two of them. These extra seats will be

Velcro'd in and possibly made a little more adjustable with added velcro in

different areas of the hull. Or, left out completely if need be. Man, this

thing is going to weigh a ton. (approx. 1 hr.)

27 Sep 04:

Pulled the outer Gunnals off the boat and

cut the compound angles on the ends with my Japanese Pull Saw ( look-alike ).

Love that saw! Then I measured and marked for the tapers on all ends. Once

marked I used my block-plane to plane down those tapers. Then, since I

didn't want them laying around to get stepped on, I clamped them back on

the boat. I also did some sanding on the Seat/Support piece and it's now

ready to install. ( approx. 2 1/2 hours )

Pulled the outer Gunnals off the boat and

cut the compound angles on the ends with my Japanese Pull Saw ( look-alike ).

Love that saw! Then I measured and marked for the tapers on all ends. Once

marked I used my block-plane to plane down those tapers. Then, since I

didn't want them laying around to get stepped on, I clamped them back on

the boat. I also did some sanding on the Seat/Support piece and it's now

ready to install. ( approx. 2 1/2 hours )

9/30/04

Last night I didn't have too much time

but I managed to glue the seat/support in the canoe. I used thickened epoxy to

attach it to the support and side panels. I also added some filler around the

edges. Tonight I went back to the seat and sanded a little and applied some

glass cloth from the seat to the side wall. I also applied a fill coat to the

top of the seat. A total time ( approx 45 min. )

Last night I didn't have too much time

but I managed to glue the seat/support in the canoe. I used thickened epoxy to

attach it to the support and side panels. I also added some filler around the

edges. Tonight I went back to the seat and sanded a little and applied some

glass cloth from the seat to the side wall. I also applied a fill coat to the

top of the seat. A total time ( approx 45 min. )

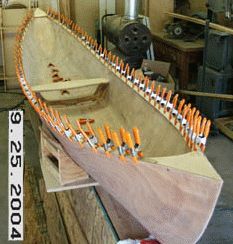

Also, tonight, I sanded the outside edges on the O. Gunnal strips and attached one. I mixed some epoxy and applied it to the inside of the strip for one side of the canoe. Then, went back and added more epoxy to the mix. I thickened it with my filler powder and applied it to the outer edge of the canoe... then added some to the inside of the strip. I stuck the strip on the canoe and started clamping. Once I got it positioned where I wanted it I got out the drill and screw tips. I drilled holes (which I had previously measured and marked) and then went back a few at a time and put the screws in. (approx. 2 hrs)