The Rob Roy as built by

Larry "Rehd" Brown, Fresno, Calif

12 Oct 04:

Gettin' close... Today I sanded the Breasthooks again with 220 wet/dry

paper. I took the canoe out in the front yard and wet-sanded the whole thing,

inside and out and washed out all the sawdust and junk. Wiped it down to dry

and hauled it back in the garage and glued in the Velcro tape patches on the

web-seat support pads. As far as I can tell, it's completed with the

exception of the Varnish and adding carry loops on the breasthooks. I'll be

waiting for about two weeks before adding the varnish. I may have to adjust the

web-seat lengths as they might be too long with the added thickness of the

Velcro tape. (approx. 1 1/2 hr.)

10-21-04:

Yesterday, I went into the garage and wiped all the dust off the boat in

preperation for the finish coat. I chose Varathane, clear, water-based Spar

Urethane to finish the boat. It's very clear, easy to apply, easier to

clean up and it's hard as a rock when cured. I applied two coats with a

2" wide foam brush. I waited approx 3 hours between coats. Tonight I wet

sanded the first two coats with 600 wet/dry Silicone Carbide paper and a pail

of water. I toweled it down and left it for a while to be sure that all the

moisture evaporated from the surface. I then applied a third coat and couble

checked it for dry spots or runs. It looks O.K. so far. The finish is really

bringing out the figure in the Okoume plywood. Tomorrow evening I'll add a

fourth coat and see how it looks. I may leave it at that and go on to the outer

hull. (approx. 2 hours total for all 3 coats).

11-4-04:

I am down to my last sanding and the carry loops. I'm going to be doing a

little catching up here as My computer was down and I was working lots of

Overtime at work. I've put on the 4th, 5th, 6th coats of Varathane and

tonoght I put on the 7th coat. I think that will be enough. Each coat I

wet-sanded the hull and allowed it to dry and then applied the coat of

Varathane. I also allowed a day or two for the previous coat to cure. Each

coat, sanding and applying, took an hour. So that comes out to ( approx. 4

hours. ).

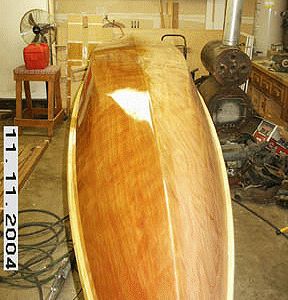

11-11-04: The past two days I have been wet sanding the outer hull with wet/dry silicone carbide sandpaper. ( 600, 1000, 1200, 1500 and 2000 ) I started with 600 grit and used it on the Orbital sander, applying the water with a spray bottle. It seemed like I might be taking off too much of the finish with this method, so I reverted to hand sanding. It took about 30 minutes for each trip around the boat this way, and then cleaning up the residue with a damp towel. Through all these grits, I was not satisfied with the finish.. it seems somewhat cloudy. I was kinda half afraid I'd applied the Varathane too soon and the epoxy hadn't totally cured yet.. so... Today, after sanding with with the 2000 grit I broke out the polishing compound I got for the cars. It's a professional grade and works like a champ. I ran the polisher over the entire outer hull including the gunnals and when I cleaned up the residue... the boat shined like a glass table top. The 'foggy' look was apparently the scratches that even the fine paper was leaving. It may be over-kill, but I also tossed on a coat of Good Quality Carnuba auto wax. Whooo-Hooo!!! What a shine.. :) Probably the only time it will look this good, but it's worth it.. Now I'm ready to flip it back over and check for possible runs on the gunnals and breasthooks, from coating the outer hull, then shining them up as well. I won't touch the inside as I don't want it any slipperier than it has to be... this worked out to ( approx. 4 1/2 hours total ).