APPLICATIONS: Making scarf joints

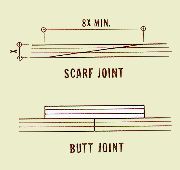

A scarf joint is made by joining two members having tapered, beveled, or chamfered ends which lap together, as opposed to a butt joint where squared ends of the mating members simply butt together. A scarf joint gets its strength primarily from the ample glue surface area. Scarf joints are used to make longer members where single members of sufficient length are not available, or are too costly. Both solid wood members and sheets of plywood can be scarf joined. Using either "POXY-GRIP" or POXY-SHIELD®, with proper methods, such joints will be amazingly strong, exceeding that of the joining wood members.

With scarf joints, it is preferable for the members to fit as closely as possible for ultimate strength. However, minor irregularities of fit are acceptable since the epoxy will have the ability to bridge these without significant loss of strength. The amount of taper with a scarf joint is usually stated as the ratio of the thickness of the joining members to taper. A common and recommended ratio is 1:12; that is, the length of the taper is 12 times the thickness of the members. In other words, members 1" thick being scarfed joined would have an overlap or scarf 12" long.

In theory, higher ratios are stronger, while lower ratios are weaker. However, experience shows that in thicker members (especially those not subjected to great bending stress), a ratio of 1:8 is acceptable. We feel that this range (between 1:8 and 1:12) is satisfactory for most uses when our epoxy products are used, whether scarfing solid wood or plywood members.

While the methods for cutting, fitting, and making scarf joints are generally covered in most wood boatbuilding texts (which the user should consult), some additional remarks can be made. Adjacent scarf joined members should have joints staggered from each other as a safety precaution rather than being located all in one area, such as in the middle of the hull. Also, the number of scarf joints should be held to a minimum, using members as long as possible since they take time and care to make. It is often helpful to use a couple of nails to keep the joint from sliding out of position. The fasteners can be standard finish nails, with heads protruding for later removal.

The use of epoxy (since it is superior to other marine glues) should not be considered an excuse for a poorly made scarf joint; care should still be taken since there will usually be no fastenings to hold a joint together if it fails. However, if you have doubts about a scarf joint, it is still usually possible to salvage the situation by installing a backing member. This would be similar to the butt block member used to back butt joined members. If used, it should be of the same thickness as the joining members, lapping several inches either side of the joint. Alternately in solid wood members, fastenings can often be used to supplement strength at scarf joints.

When gluing up scarf joints, the latitude of the epoxy products makes several approaches possible, and builders devise different ways which appeal to them; there is probably no single "ideal" method. You can use "POXY-GRIP" alone, or "POXY-GRIP" over joints pre-coated with POXY-SHIELD®, or POXY-SHIELD® alone when properly thickened.

We prefer one of two methods. In either case, the principal is to provide as much glue as the joint will absorb to prevent glue-starved joints. With solid wood members, the joint will present an end-grain situation and probably absorb a good amount of glue. With plywood panels, because of the cross plies, there will be alternating flat and end-grain areas exposed, so more resin should be applied on those plies in the end-grain orientation.

In the first method, coat the joint with straight POXY-SHIELD®-Fast and let set for 5 or 10 minutes. Then recheck and apply more resin until dry spots no longer appear. Before the resin sets up, apply "POXY-GRIP" liberally and clamp or hold the members in position until the glue sets up, cleaning up excess glue as required.

The second method is similar to the above, however, POXY-SHIELD® is used throughout, with Silica filler added to make a syrupy consistency. Apply this mix to both mating surfaces and allow to set for 10 to 15 minutes. If there are no dry spots, the members can be clamped and held in position. However, if the resin has been absorbed and dry spots have appeared, apply another liberal coat and then clamp the members.

Scarf joints or other joints that will be put under stress when unclamped should be allowed to cure 5 to 7 days, when it reaches its full strength, before removing clamps. In circumstances when temperatures drop below 60oF at night, or for other long periods, the clamping time should be increased as at lower temperatures curing slows considerably.