Building the Malahini with Dad

by Alan Bates

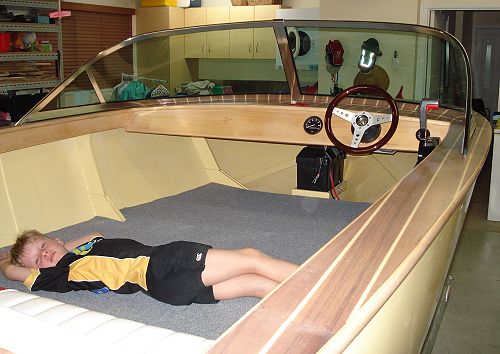

18. This is a good shot showing the position of the battery box (and my son, Jack). The windscreen and carpet are also in place, and in keeping with the era of the design, I have gone for the minimum number of (analogue) gauges.

19. Have a look at this! Firstly, you'll note the edging on the motor well cut-out. It was cheap aluminium table edging that Dad bent to shape, using the scrap piece of ply cut out of the top deck for the motor well. What a great result, and cheap too! (I must have Scottish ancestry). The second thing to note is the unusual steering arm on the outboard. Because I opted for an outboard motor with a standard shaft length of 20", the cut-out in the transom was made 5" shallower than the plans provide for (the plans are based on a 15" shaft length). That was all good, and I would do the same thing again tomorrow. The problem was that when it was time to fit the outboard, the steering arm fouled the top deck when turning the steering wheel to the left. The engine installer offered to cut out part of the top deck to make it fit!!! NO WAY! A friend with an engineering shop re-manufactured the steering arm out of flat stainless steel bar, and TIG welded in a countersunk stainless bolt. This was tricky, so just think about this modification carefully if you need to do it.

20. Harry and Jack test the new upholstery, and windscreen.

21. Well, Sophia made it to Noosa with us in April, 2007, and I think she looks great! Nine months from start to finish, and about AUD$20,000 to build. And she also allowed me to spend some memorable time with my Dad. Oh, and my wife and kids think that it's great!

22. I chose the 50hp Tohatsu 2-stroke because it was the lightest 2-stroke available at 82kg (180lbs), and their fantastic reputation for reliability. It pushes Sophia along at 42mph.

23. Goodbye! I couldn't be happier ...But I did see a mahogany cruiser at Noosa over Easter, so I might start looking at some of those Ken Hankinson designs...