WebLetter 24

An Occasional Publication for the Home Boat Builder

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

- Sculling oar

- Rigging Small Sailboats - Chapter 11

- Hercules in stitch and glue

- Old Boat Club

- Feedback: Swish

- Recent email

GLEN-L Update

How this WebLetter is made...

We try to publish the WebLetter every 4 to 6 weeks. Selected

email and feedback that we receive from our builders is added

as received. We have been running the book Rigging Small Sailboats which has to be

typed, formatted, and photos scanned. When I have time, or to

answer a question, I write an article, put in a link, or

reproduce something from our existing literature. The week

before publication, everything is checked, additional

articles or features added if necessary, it is proofread, and

links are created from other parts of Glen-L.com. We really

want the WebLetter to be of help to you boat builders out

there, but there are only so many hours that I can devote to

this, which is why I appreciate your input. I assume that our

readers are interested in boat building and are looking for

useful information. As you find answers to your own

boatbuilding problems, how about writing a description and

emailing it to us. We'll share it with your fellow

builders.

- Website:

- For those of you who read the article in WebLetter 23 about the stitch and glue Sweet Caroline by Richard Barnes, we have added 12 additional photos of construction with Richard's comments. You might want to revisit if you are interested in his project.

- Thanks to Frank for his corrections and addition to the List of Lumber Suppliers.

- Thanks also to Greg Stender, Steve Parsons, and Hans Binsch for their input on sculling oars. Also George Robinson, Todd G. Williams, and Jim Cassidy, as well as those who sent email.

- We finish posting the book Rigging Small Sailboats in this issue. Next month we will start a new series: "Designer's Notes". These are notes our designers have made to aid in answering builder questions. So stay tuned for the first installment of these never-before-published gems of boat building knowledge.

Barry Witt

Editor

Pattern Transfer Paper

The best thing since full size patterns.

Learn more

Sculling oar

Do your Oar & Paddle plans have details for a sculling oar of the type used in the Scull Boat?

Answer: Our plans have spoon-type sculling oars, but

these are not the type used for the Scull Boat...

I put an inquiry on the Duck

Boat/Hunter Forum for an answer to this question. I

received the following from Greg Stender, Steve Parsons, and

Hans Binsch.

January 11, 2001

From Greg Stender

Barry,

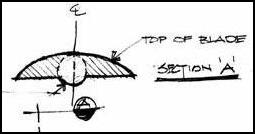

I hope you can sort through my ramblings and be able to understand a Humboldt Bay scull oar, as I try and describe them. I don't consider myself a master sculler, that is reserved in my mind to those who have gone before me, rather I would rather just like to point to them and call them the true masters. I have included some photos of scull oars that I have collected, and a few that I have built over the years. Also a free hand sketch that I drew some time ago to compare notes with some of my East Coast sculler friends, I figured a sketch is worth a thousand words. You may use this for your newsletter also if you desire to, however I am the creator of the drawing and retain copyright on it. I have no invested interest in scull boats or oars, meaning I don't make or sell them for others.

Over the years I have seen scullers fall into two classes or attitudes to sculling. One "low and fast" and the other "high visibility and methodical". I don't believe there is an oar that could be considered the "perfect oar" for all the different boats and scullers that are out there, considering all the factors that come into play for sculling. The type of sculling that I mainly do is all open water stalks. In my opinion speed is crucial to be able to scull into wind waves and tidal currents on divers (canvasback scaup). At 50 or 60 yards a "street wise" raft of divers will start to swim when they see your approaching boat. A sculler has got to be able to close the distance in minutes to be able to put the boat on them before they can figure out if you are supposed to be there or not.

About oars, it really is a matter of experimentation on the users part to find the combination of blade width, length, curve, and flexibility that works best for him. My definition of "the perfect scull oar" would be one that offers the best boat speed with the littlest amount of energy spent to use it. A person that has been sculling for several years will soon have his boat "tweaked" from bow to stern to fit his personal specifications, will have many scull oars and one probably still in experimentation. I believe a glass over wood oar is the easiest way to find the oar that works the best. A person can start with a very thin bladed oar that has a lot of whip in it (probably the easiest oar to learn on) and can stiffen the oar with additional layers of cloth to "stiffen" it up as he wishes, and as his or her sculling progress with time. It is my theory that a glassed oar can store and release more energy than a solid wood one. That type of oar is what I was first introduced to when I began sculling, and all the "coveted" oars from Humboldt that I have seen have been of that design (glass over wood and two piece.) I hope this helps some, and helps describe one of the many regional styles of scull oars that can be found across our country. Keep up the great work at your company, maybe one day I will have the opportunity to scull one of your company's scull boat designs, my desire is to scull them all. Take care, Greg

Greg's drawings, photos, and other responses

Feedback: Hercules in Stitch and Glue?

by George Remington

I talked to Glen before starting the Hercules. We discussed lengthening the boat by adding 4" to each frame station interval after Frame 6, to lengthen to 26 ft., and I have done so. The effect on the interior accommodations is dramatic. I now have 7 ft. by 30" berths both sides of the main salon, and, in addition to an 8 ft. length of counter for the galley, we have added a co-pilots chair in the pilothouse, forward portside. I also added a footwell forward for anchor handling, shoved the cuddy forward and put the fore hatch in the cuddy cabin top. All has worked out beautifully without any change in appearance to any but a very discerning eye.

The biggest difference in the boat is that I used the frames as molds for a wood-epoxy hull, covered the mold with plastic, and laid up 5 separate panels ( transom, P&S sides, P&S bottom). The last layer on the sides was longitudinal mahogany at 3/16" thick, as well as the bottom bow above the waterline. With these removed, I took off patterns for a cradle at Frames 2,4,6 and mounted them on a wheeled platform (6 ft. x 16 ft.) Reusing the keel/stem assembly, which was laminated to retain it's shape, I put the panels together using stitch-and-glue lamination.

After installing bulkheads (minor shuffling, to height of stem only), I wheeled the dolly outside, turned her over, and with the cradle removed, back on the dolly. Back inside, we finished the exterior.

I cut a slot in the keel assembly, and installed the core of the deadwood, after cutting , hollowing, and gluing in a piece of 1 1/2" ID PVC pipe in for the shaft. ( I cored it with a greased 1 1/2" dowel to insure straightness.) This way the inside of the shaft is absolutely sealed against water and borers. This allowed me to string line the deadwood core insert for alignment, and epoxy fillet it for perfect line-up. This sounds like a lot of work, but required no special boring tools, perfectly sealed the hole, and guaranteed alignment, all single-handed. That would be difficult do do on a 6 ft deadwood hole by other means. Interestingly, I've never seen this idea written up anywhere.

The rest of the deadwood was glued in place, reinforced with biaxial 17 oz., and the bottom finished to the waterline with two layers of dynel, covered by copper-poxy bottom finish (guaranteed for 10 years). Above the waterline I used 1.5 oz. fiberglass cloth and a very low-viscosity high-clarity epoxy. This lets the mahogany shine through like a varnish job.

At this point the boat was wheeled back out, turned upright and put back on the re-installed cradle. Here's where the job stalled. I needed more than the 9 ft. clearance on my shop doors to allow construction of the superstructure. So I built a 30 ft.x 20 ft. shop extension with 16 ft. ceiling, and a 12 ft. wide x 15 ft. high door. With the Hercules back inside, I had room to complete.

New Feature on Glen-L site: The Old Boat Club

A Project Registry for Glen-L designs built from 1953 - 1980. For those who would like to communicate about maintenance, re-building, and repair.... Old Boat Club.

Feedback: Swish

by Todd G. Williams and Jim Cassidy

Email 22 Dec 00:

We found this boat parked by the side of the road and decided that it needed a new home. (The Swish is a 15' version of the L Dorado and L Capitan.) The boat is complete with everything including the original 35 hp Elgin outboard.

The decks and the transom needed replacing and some of the frames needed reinforcing but the boat was basically solid. After some delays (family and business took priority), we now are back on track. All the structural work is now done and the next step is to re-glass the seams finish the bottom and replace the decks. It is now well wrapped for the cold Connecticut winter.

Recent email:

Subject: Project registry

Date: Wed, 24 Jan 2001 23:10:03 -0500

BASS BOAT / Brian Eager / 01-24-2001

Project complete, probably. This boat was built by my father

Dale Eager, brother Steve and I, starting in late 1975 or

1976. We were inspired to build when Dad and I got our

backsides wet in a two seater kayak-style Folbot design that

we had built 3 or 4 years earlier. Started from the frame kit

and worked on the project in the evenings and on rainy days

when the farming work was not pressing. We thickened the

transom with another 1/2" layer of plywood, and sawed

out a full 2x4 (actual dimension) oak crossbeam for

additional stiffening. Frame layout, longitudinals and

planking were done in the driveway of a corn crib, then we

moved the hull into our wood shop (Refitted chicken coop) for

the fiberglass application. No big door, we put it in and

took it out on edge through the walk-in door. We are powered

with a 1958 Johnson V-4 50HP short shaft, it will make about

32 mph at full throttle and consume 6 gal/hr. Reducing power

by 1/3 will still translate into around 27 mph and the fuel

flow drops to 3 gph. The boat was a great pleasure to build

and is still giving us good service 25 years later.

Subject: Registry - Sweet Caroline

Date: Sat, 20 Jan 2001 00:15:07 -0600

Sweet Caroline Update, Donald Hodges, Lynn Haven, FL

As of January 2001, most remaining work is fairing/painting.

Scheduled for one week cruise in Florida Keys beginning

3/10/01, so launch date is mid-February. Progress photos and

paint scheme sketch on website: http://www.ecoastlife.com

January 20, 2001 at 21:46:16

------------------------------------------------------------------------

name: keith howell

Comments: I built the Carolina Dory skiff and like it very

much, easy to build, inexpensive, and handles great in almost

any water condition.

Below is the result of your feedback form.

Friday, December 29, 2000

------------------------------------------------------------------------

name: Brian Amato

Comments: It all started with me building "The Eight Ball" back in 1974. It came out so well, and was such a "ball" to sail....that I'm now building another one here in 2001 !!

You guys are by far the best !

Every one of your plans turns out a terrific boat and your

phone help is terrific. I recommend you to everybody.

Sure...there are newer....glitzy designs out there but if you just want to build a proven boat from proven plans...from a proven supplier, go with Glen-L !!

Brian Amato

Traverse City, MI

Subject: waterproofing inside of hull bottom below

cabin/cockpit floor

Date: Thu, 21 Dec 2000

Hello Glen-L

I am a first time builder, making your Minuet. ....

Also, I'd like to say I'm having a great time so far. Just reading the plans has been challenge enough for me. I'm very glad I spent the extra nickle on the pre-fab frame kit. I could never have duplicated the precision assembly you sent me.

Sincerely,

Jim Doucet

Calgary, Canada

This is a June 2000 letter I found in my "do something with this" pile.

To Whom This May Concern:

In 1965 as a young man of twenty five, I sent to you and received the plans to build your design the GLEN L #10. I spent a glorious year in Minneapolis building this marvelous little sailboat with my own hands. I also spent many a happy hour sailing it all over the lakes of Minneapolis/Saint Paul. I finally sold it to a friend here in Great Falls and his two sons have about worn it out. Later I suggested to a group of Optimists that as a fund raising project we build "The Stripper" canoe and raffle it off. Unfortunately the club broke up. None the less I built the stripper myself and my "boss" offered me a thousand dollars for it and I never had it out in the water. He promptly tried it in a group of white water rapids near Wolf Creek Canyon. I tried very hard to tell him it was never designed for that so promptly charged him five hundred dollars to return it to it's former glory. ... (He is not my boss any longer but I don't have the money to return his thousand dollars but believe me if I could I would buy my baby back Oh well.) I just turned sixty (January 2000) and have two years before my early retirement. ...

Sorry to take so long to tell you my needs and/or requirements but I thought you might be interested in a little history of how GLEN L has been instrumental in taking part in my life. I don't know which is the most fun, the building or the using of the end product.

Most Sincerely

Jerry A. Hurley

Subject: Frame kit

Date: Thu, 7 Dec 2000

From: EL Anderson

Just had to write and tell you how UNDERPRICED your frame kit for the GL15 is. On top of the very low cost of $500 plus the quality is far more precise than I'd ever be able to accomplish.

To prove my point of the low pricing of the frame kit the local lumber yard, where I buy my materials, charged me $468. for the Keel, Chine Logs, Sheer Clamps, etc. Only 4 items required milling (Keel, Carling, etc) and the rest were standard mill measurements. That' only 13" stringers"!!!!! Part of this amount was a milling charge of $100.!!!

Glen-L should be proud!!!!

Wednesday, December 6, 2000

-----------------------------------------------------------------------

name: Chad George

Comments: Me and my dad have the Missile that my grandfather built in 1959. We sold it after buying a daycruiser and kicked ourselves after. About six years after that we found it by accident looking for parts in the paper. It is now in the garage waiting to be restored. Thank you for bringing the Missile back. You have made a father and son and grandson very happy.

Build more boats

Glen-L boats, of course