BOATBUILDING WITH PLYWOOD, by Glen L. Witt

CHAPTER 5 - LUMBER

Page 2

Lumber Defects

Rot & Worm Protection

Sapwoods & Heartwoods

Softwoods & Hardwoods

SELECTING LUMBER

Once a source of lumber has been found, and a type of lumber has been decided on, the next step is the selection of the lumber or actual boards that will be used. As previously stated, wide widths are usually preferable, especially if facilities are available for re-sawing or ripping to size. Also, long lengths are desirable. But what do you do when the plans call for a member 20' long and the longest member available is 12'? As will be covered in forthcoming chapters, such long members can usually be formed from two shorter lengths by means of a scarf joint or butt joint. However, the builder must check against his plans to assure that such a joint will be located at the most appropriate location. For example, while two 10' lengths could be used to make a 20' member, utilizing a butt joint and butt block, it is possible that the joint would be located in an area of the hull with severe curvature which would make the joint more difficult to make. On the other hand, a 12' and an 8' length, which would also make up the 20' member, could be utilized that might locate the joint beyond the curvature thereby simplifying the joint. In other words, the builder should check all options against the plans in order to select the most suitable material, considering all such joints and lengths that may be required.

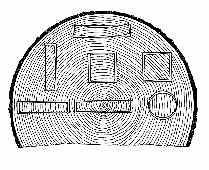

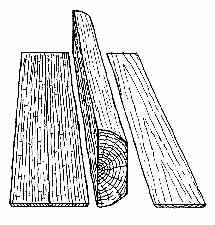

Ill lumber used in boat building must be seasoned, which means that the moisture from the green wood has to be removed in order to improve its serviceability. Air drying and kiln drying are the two methods used for lumber seasoning, and generally speaking, the air dried process is the best for boat building woods. However, air drying can require a year or more depending on the thickness and wood species, and consequently is seldom done. Most of the lumber available is kiln dried, which is acceptable if done properly. However, if the kiln drying process is either rushed (leaving too much moisture in the wood), or the lumber is "cooked" too long or at too high a temperature, (thereby removing too much of the moisture and making the wood brittle), the lumber will not be suitable for boat building. For most boat building lumber, the ideal moisture content ratio to lumber weight after drying (regardless of the process) is approximately 15%, with a range of from 12% to 16% being acceptable. When the wood is seasoned, it shrinks to some degree (see Plate 5-B), and if during PLATE 5-b: How a piece of lumber will shrink with seasoning depends on how it is shaped in section and where it is cut from the tree. Tangential shrinkage (in the direction of the annual growth rings) is about twice as great as radial shrinkage (along the grain). The flat board at the lower left features the ideal vertical grain which makes such strinkage uniform on all faces.

PLATE 5-b: How a piece of lumber will shrink with seasoning depends on how it is shaped in section and where it is cut from the tree. Tangential shrinkage (in the direction of the annual growth rings) is about twice as great as radial shrinkage (along the grain). The flat board at the lower left features the ideal vertical grain which makes such strinkage uniform on all faces. |

But how does the average person detect lumber that has been properly seasoned and is within the range of suitable moisture content? Here it is largely a matter of depending on the integrity of the lumber dealer. However, there are tell-tale signs that one can look for when it comes to selecting suitable boards. Lumber that is "green" or unseasoned will often actually be "wet", with moisture apparent especially between boards when one is lifted. Of course, such lumber will be considerably heavier than comparable seasoned wood. Conversely, lumber that has too little moisture content may appear to be dry or even "weathered" as well as brittle. Lumber that has been kiln dried too "hot" or quickly will often be warped, cupped, or wind severely along its length. These boards should be avoided even though the defects may only appear to a minor degree. When such boards are re-sawn after purchase, the problems are often magnified and can make it unusable.

Ihenever possible, boards should be selected that have prevalent vertical grain (also known as "edge grain" or "rift sawn" stock). Such boards will tend to expand and contract uniformly without undue distortion. When a lumberman cuts a tree, he has two ways available that he can cut the log up into boards. The easy and quick way is to simply slice up the log or "plain saw" it (see Plate 5-C). With this method, only a few of the boards will have the ideal vertical grain pattern, while most of the boards will be of flat grain (the terms "plain sawn", "slash grain", and "flat grain" are synonymous). Such flat grain boards tend to "cup" or distort, and therefore can split or check more easily. If the lumberman wants to take more care, he can cut the logs by what is called the "quarter sawn" (see Plate 5-C) method. PLATE 5-c: Quarter sawed lumber results in ideal vertical or edge grained boards (at left of log), while plain sawed lumber provides boards of flat grain (to right of log) which are not as desirable for most uses in boatbuilding.

PLATE 5-c: Quarter sawed lumber results in ideal vertical or edge grained boards (at left of log), while plain sawed lumber provides boards of flat grain (to right of log) which are not as desirable for most uses in boatbuilding. |

LUMBER DEFECTS

Once lumber of suitable grain structure has been selected, look for defects. Some people confuse defects with blemishes. A blemish as such does not affect the serviceability of the wood, but merely mars the appearance. A blemish can be important, however, where the natural grain appearance of the wood is desired, such as with joinerywork. A defect, however, is an irregularity in or on the wood that may lower its strength. It is often difficult for the novice to detect defects or to understand their consequences. In many cases, a defect will be limited in area and can be worked around so that it can be cut away, or will otherwise end up in a member or area where a decrease in strength is not important. So depending on the defect and its extent, don't rule out an entire board simply because of a limited defect. It is often possible to get a discounted price on such a board.

Defects usually are of two types; those caused by seasoning, and those that are caused by the way the tree grows. Seasoning defects are usually the result of shrinkage caused as the moisture is removed. Checking is a common seasoning defect, and it is a tension failure causing a split either along the surface of the board, or at the ends. An actual split in the wood is more severe than checking and is usually caused where an end check and a surface check meet. Warping is said to occur when the faces of the boards are no longer true planes. Warping defects include: bows (lumber bowing along its length), crooks (distortion of the edges of a board so they appear concave or convex), cupping (a concave or convex appearance when viewed on the end edge), and twisting (when the four comers of a board are no longer in the same plane). A major problem with bows and twists is that while the warp may be minor in the board, the problem tends to magnify when the board is re-sawn. On the other hand, cupping can be reduced if the board is re-sawn into narrow widths. Likewise, on a board warped lengthwise, shorter lengths of the same board can minimize the problem. While there are other seasoning defects, checking, splits, and warping are the ones that are most common and easily detected by the novice.

Natural defects that are a part of the lumber caused by growth can vary considerably with the species of lumber. For example, Sitka spruce is a very straight grained wood with few natural defects. However, Douglas-fir frequently contains knots to one degree or another, and it is often difficult to find the desirable dense, vertical grain type free of excessive knots. Knots are probably the most common natural defect, however, a knot in itself may be acceptable if it is minor in size in relation to the rest of the piece of wood and is tight with the surrounding wood. Whether a knot can be accepted in a given board depends not only on the soundness and size of the knot, but what the board will be used for. For example, if the board will be used for a bending member such as a sheer clamp or chine log, a knot along the length of such a member will often be unacceptable. Such a member if it does not break during installation, may fail in use at the knot.

Cross-grain in wood occurs when the fibers are not parallel with the major axis of the piece of lumber. Two types of cross-grain include diagonal grain and spiral grain. Cross-grained wood is not too commonly seen where boat building lumber is sold, partly because such wood is difficult to machine or season properly. Cross-grain wood should be avoided because such wood will fail under stress at the point of the cross-grain.

A shake is somewhat like a check or split except that shakes do not develop in seasoning or handling, but originate in the green timber. They may, however, become more apparent during seasoning. Depending on the location of the shakes, they may weaken the member. However, in boat building lumber, shakes are not too common because they occur mainly in lower grades of lumber that are not located near the heartwood of the tree.

Decay and rot can exist in wood before it has been installed in the boat and is almost always caused by fungi that grows in the wood. The decay and rot of wood after it is in the boat, its causes, and prevention is discussed later in the chapter, even though they are similar. An unusual fact of decay in wood is that all tree species are subject to heartwood decay in the living tree. However, once the heartwood lumber has been cut and seasoned, its decay resistance tends to increase, and in some cases, increases significantly depending on the species. On the other hand, rotting of sapwood in living trees is rare, but cut and seasoned, the resistance to rot is low. Therefore, decay that develops after the tree has been cut, and before use, of the lumber, is likely to be found in the sapwood. Such decay is usually easily seen and is often white or brown in color, with the surrounding wood greatly softened, punky, pocketed, brittle, collapsed, or cracked. Luckily such lumber is not commonly seen in a reputable lumberyard.

A common mistake by the novice is to confuse decay with insect damage. Insect damage is recognizable as holes in the wood and is classified as pin holes (or "pin-wormy" in some species), grub holes and powder post holes. All these insects are normally killed with kiln drying, or by wood preservative treatments. Insect damaged wood should not necessarily be automatically rejected. Much depends on the extent of the damage and where the wood will be used. Powder post damage (usually found in the seasoned sapwood of such woods as oak or ash) can destroy most of the interior of a piece of wood while the surface shows only minor holes, thereby reducing considerably the strength of the member. The other types of insect holes show up on the surface and the extent of damage thereby can be more easily determined.

ROT & WORM PROTECTION

On one hand, there seems to be a lot of talk bandied about by so-called "experts" about worm and rot "dangers" on wood boats. Yet on the other hand, finding a wood boat that is 50 years old or even older in sound condition is easy. In many cases such venerable craft seem to be unscathed by these purported "villains". Why is this so? The simple answers include using proper materials in the construction, proper construction techniques that will make the boat suitable for the conditions where it will be used, and proper maintenance.

To go into the technical aspects of this subject would not only be beyond the scope of this -book, but would also be boring to the average boat builder. All that is important from the viewpoint of the average do-it-yourselfer is how to protect his craft from possible damage from rot or worms.

Protection from worms is relatively easy on most plywood boats and is seldom a problem at all. First of all, marine wood borers (the worms that can cause damage to wood) are not found in all waters. They are usually limited to the warmer waters common to tropical areas. If worms are common to the boating area where you are located, this will usually not be a well-kept secret; the boaters in the area will know if they are there.

Wood borers tend to invade some woods and not others, so in selecting woods that will be exposed underwater, those woods that are less subject to attack should be used. If such woods are not available, they should be treated with a suitable wood preservative or pressure treating technique. However, on a plywood boat, there is usually not much solid lumber below water with the exception of skegs or deadwood keels. Unlike solid lumbers, marine borers do not seem to like plywood nearly as much as some solid lumbers. One reason that this may be so is the glue line between plies that is distasteful or even toxic to them. Another aspect is that the edge grain is more susceptible than the surface of a panel, and sealing the edge grain for protection is easy.

Of course, a plywood boat that is entirely sheathed with fiberglass or equivalent material and resin is virtually immune from worm attack, and hence this is probably the easiest method of protection where attack by worms can be expected. Worms do not seem to like or be able to penetrate surfaces covered with the resins (either polyesters or epoxies) used with these sheathings.

There are different kinds of rot and reasons for their spread, but to keep things simple, rot requires moisture, lack of air circulation, and the proper temperature to spread and grow to cause any damage. Remove any one of these factors and rot will usually not be a problem in any wood boat. As with worms, using a rot resistant wood will be the first step in rot prevention.

Most boats tend to accumulate some water in the bilge. If the boat is used in salt water, it is a common mistake to assume that this bilge water will cause rot. The rot fungi cannot grow in salt water; they need fresh water to be promoted, and consequently most rot tends to occur along the deck and cabin areas where fresh water or moisture (from rain, condensation, etc.) tends to penetrate into the structural members.

With conventionally built wood boats this is more of a problem than with plywood boats since the deck and cabin areas are likely to be covered with fiberglass or equal sheathing on the plywood boat. Nevertheless, a positive and adequate flow of air should be provided to all below-decks spaces, especially in the ends of the boat, This is not-ably important when the boat is not in use. Remember that rot can occur whether the boat is kept in the water at a mooring, or in the backyard on a trailer. So if it is kept covered regardless of where, take into consideration that air must flow inside. (Note that this rule applies to ALL boats regardless of the material used in the construction.) Temperatures should be kept down also since rot spores are not active at lower temperatures.

In building a plywood boat, the recommended technique for rot prevention, besides using suitable materials and proper maintenance, is to liberally apply wood preservative to all surfaces inside the hull. If the hull is to be sheathed with fiberglass or equal material and resin, this treatment should not be done until after the exterior of the hull has been covered since the resin will not bond to any areas where the preservative has been applied. For example, if the wood preservative liquid happens to penetrate through a joint, say along the chine, and gets onto the outside of the hull, the resin will not form a bond at this point. So apply the preservative after the hull is righted and the fiberglass covering has been completed.

There are several types of wood preservatives available under many brand names from paint dealers. Two common types are pentachlorophenol and copper napthanate, and these ingredients are usually noted on the fine print of the label. Follow the manufacturer s instructions carefully for proper protection. With most of these treatments, painting of the surfaces can be done after, but be sure to check the label.

A common mistake often is made by the amateur in assuming that if a fiberglass covering will protect the outside of the hull, why won't it do the same for the inside? The problem is not the theory in this case, but with the application. It is virtually impractical to properly apply the fiberglass cloth around all the many corners and junctions within the hull so that it will bond 100% at all areas and not lift thereby forming air bubbles. If any air bubbles at all form in such a covering and go unnoticed, they will eventually form perfect moisture traps that could lead to rot. Since the bubble where the rot will start will be a small area, it won't be noticed on the surface, but the rot could spread under the covering and do a tremendous amount of damage before it is detected. By this time it could be too late and quite a repair operation would be necessary. In short, such a procedure is not recommended; let the interior of the hull "breathe" instead, using the recommended preservative treatment and later painting the hull interior areas if desired. Note that fiberglass laminates are hygroscopic, that is, they will absorb moisture to some extent (contrary to popular belief).

SAPWOODS & HEARTWOODS

Basically, the heartwood is the middle of the tree, while the sapwood is the layer surrounding the heartwood. Actually, the heartwood consists of dead cells, and year by year the tree increases in diameter by the addition of new layers of sapwood under the bark. As the outer layer of cells increases under the bark, another layer of cells dies off in the sapwood and changes to heartwood. As previously mentioned, sapwood in practically all trees is low in decay resistance, and unless given preservative treatment, is not as durable as heartwood.

Heartwood is neither weaker nor stronger than sapwood fundamentally, but some changes in physical characteristics do occur with heartwood formation. For example, the heartwood absorbs and loses moisture more slowly than sapwood making it more dimensionally stable. However, most heartwood is more difficult to treat with preservative although many varieties are more resistant to decay in the heartwood. While the heartwood of many trees is readily distinguishable from the sapwood by virtue of a darker color, some woods show little color differential. Good all-heartwood lumber may be difficult to obtain, and it is common to find boards with both heartwood and sapwood combined, depending on the species.

SOFTWOODS & HARDWOODS

Woods are grouped into two general classes; hardwoods and softwoods. However, the terms do not necessarily mean that a hardwood is harder than a softwood. The difference between the two classes is purely genetic or botanical in nature. Hardwoods come from trees with broad leaves (called angiosperms), many that tend to drop their leaves with the seasons. Softwoods, however, come from trees that have needle or scale-like leaves (called gymnosperms), are mostly evergreens, and are often called conifers since they are cone-bearing trees. Within each classification there are considerable variations in structure and qualities. The main thing for the novice to remember is that when someone, such as a lumber dealer, refers to a wood as a "hardwood" or as a "softwood", he will be referring to woods with a botanical difference; not to a wood that may be harder than another.