A P A

The Engineered Wood Association

BONDING FIBERGLASS TO PLYWOOD

Plywood has been used as structural stringers, transoms and decks in boats for decades. In these applications, the plywood is often overlaid with fiberglass. Some boat manufacturers have moved to eliminate wood components from boats due to risk of fungal decay. Preservative-treated plywood has become a preferred choice of some boat manufacturers; others have had negative concerns about the use of treated plywood.

Study Objective

A limited study was undertaken to evaluate the bond strength of typical fiberglass systems to treated and untreated plywood samples. The primary objective was to assess whether common preservatives used for plywood would have an adverse effect on bondability. A secondary objective was to assess the effect of elevated plywood moisture content on bondability. Results of the study form a basis to develop recommendations for a Best Practices Guide, which is available from APA, for plywood used in boat manufacturing applications.

Study Parameters and Methods

A study plan was developed with a marine testing laboratory in Florida to evaluate two common resin systems on three plywood species (Douglas-fir, southern pine and larch). Treated plywood sections (CCA @ 0.40 pcf retention) and matching untreated sections were preconditioned at 65% and 90% humidities to provide two moisture content ranges.

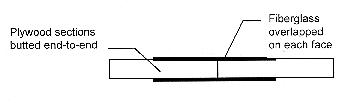

Due to the number of variables in the study, the number of panel replications was limited to two panels for each combination of species-treatment-moisture condition. Plywood sections were butt-jointed by a fiberglass overlap on each face.

The jointed plywood sections were cut into test specimens for each of three test modes:

- Tension along the length (lap strength) (five tests per plywood type)

- Tension perpendicular to the faces (five tests per plywood type)

- Bending (three tests per plywood type)

For each test mode, the load and failure type was measured. The type of failure assessed whether the fracture occurred at the plywood/fiberglass interface, indicating less-than-perfect bond, or whether failure occurred in the plywood itself, indicating the fiberglass transmitted the load across the butt joint.

Results

The influence of the treatment and moisture content on fiberglass bondability was assessed by two measured results:

- Whether failure occurred in the plywood or at the fiberglass/plywood interface

- The load at which failure occurred

All tests on the untreated and treated specimens at the 65% relative humidity failed predominately in the plywood, indicating a good fiberglass bond. This indicates that the treatment did not have an adverse effect on bonding at this moisture level. Furthermore, the strength of the treated and untreated plywood were similar.

The effect of the 90% relative humidity led to some failures at the plywood/fiberglass interface indicating poor bond. This occurred for some untreated and treated plywood types.

These results lead to the conclusion that the most common treatment for plywood, CCA, does not adversely effect the bondability of fiberglass to plywood at moderate moisture content at the time of lamination. Elevated moisture contents, whether treated or untreated, adversely effects bondability.

Recommendations for using treated plywood for boat manufacturing will stress the importance to obtain properly redried material. Proper handling to minimize moisture exposure is also important.

Technical Services Division

September 1998

©1998 APA - The Engineered Wood Association

7011 South 19th Street . P.O. Box 11700 . Tacoma, WA 98411-0700

Telephone (253) 565-6600 . Fax Number (253) 565-7265