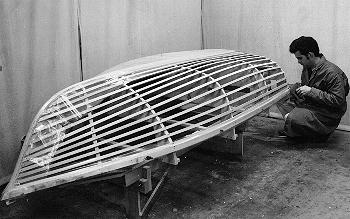

Fig. 3 Areas of the hull which are to be solid fiberglass laminate (i.e., keel, sheer, and stem) must be covered with a parting film or release agent in order to prevent the resin from forming a bond to the form members. Here, polyethylene sheeting is used, stapled in place. Optionally, the entire form could be covered with the material. Note that the form is high enough to allow access to the underside or interior which is necessary on all boats. After the ribbands have been applied and checked for fairness, and the parting film or release agent applied, the foam application can be made.

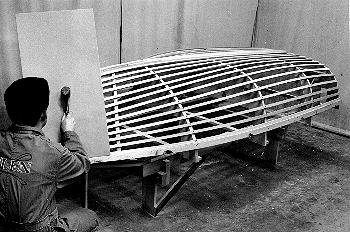

Fig. 4 The foam application can begin in most any area, however, the builder should make a check to determine the best usage of the material to minimize waste. The large sheets can be cut into virtually any shape or configuration to conform to a given area or contour. Here a panel is leaned against the form and tapped with a mallet. This transfers a mark to the panel so it can be cut and fitted in place. Note that the foam piece is resting on the edge of the sheer member. The foam can be easily cut and trimmed with a knife, hand saw, or power sabre saw. Continue