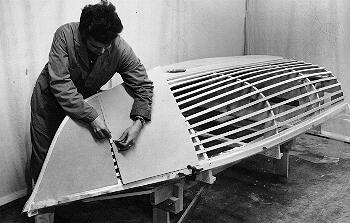

Fig. 5 When the foam pieces have been cut and trimmed to size, they are held in place against the form for fastening. Here clamps are being used along with several nails around the edges into the solid wood form members. These nails will usually tear away from the foam with the form when it is removed, however, they should be kept to a minimum and located only around edges. In some cases, the nails are fitted with plywood washer blocks and used to hold the piece only temporarily while screws are driven from the back side through the battens to hold the foam in place, or for sewing the foam in place in lieu of using screws.

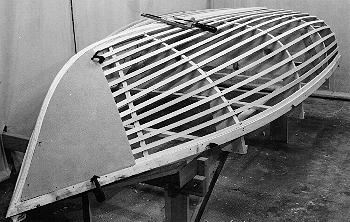

Fig. 6 Adjacent foam panels are fitted by using a small block as a marking gauge to determine the amount of material to trim away. Because the thickness of foam sheets may vary somewhat, the builder should check the sheets and use those that are adjacent to one another that are as close to the same thickness as possible in order to eliminate high and low points along seams. It is best to cut the panel somewhat oversize initially, especially if the panel must be heated in order to conform to any contoured areas. Continue