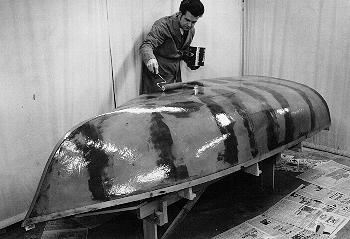

Fig. 15 Where the final hull surfaces are relatively fair and smooth, the surface can be resin coated to conceal any fiberglass material and then sanded to a smooth surface. Enough resin is applied so that the sanding will not cut into the fiberglass material, and then the surface can be painted. However, where the surface is not fair and smooth, a resin filler coat is best applied. On larger boats, it is customary to completely finish and paint the hull while upsidedown, while on smaller boats, this finish work can be done inside and outside as it is relatively easy to reinvert the hull.

Fig. 16 Cradles are made to support the hull once righted. These can be made from scrap lumber sawn to the contour of the hull section. Carpet strips are laid on the hull over wax paper or plastic sheeting at the cradle location and coated with resin together with layers of fiberglass mat. The cradles are then attached to the carpet strips with bonding angles of fiberglass mat. The form member can either be detached from the hull initially, or righted together with the hull, depending on the builder's desires and available equipment or manpower. Cradle members can either be placed separate from the hull to receive it, or placed on the hull and righted with it. Continue