After the first side panel is installed the excess along the stem is sawn off and planed smooth so that the second side will lap the first side. Here the builder is trimming the second side which will then be faired to match the first side.

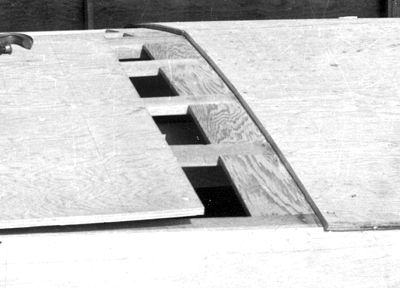

BUTT BLOCK: Side and bottom planking usually require a junction to make the panels long enough. Although scarf joints can be used, the more common method is to use a butt block. Butt blocks are usually the same thickness of the planking being used. The joint is always made between the frames (not on the frames) in as flat an area as possible. Note that separate butt blocks are fitted between the battens. The planking is temporarily held in place, holes drilled into the butt blocks, the first planking section removed, and the butt blocks glued and fastened to the planking. The next planking section is installed after the first in glued and fastened in place, gluing and fastening to longitudinals and butt block. NEXT