Building the Glen-L Yukon, Part 2

by Wayne Milner

Page 3

To try to prevent corrosion, I epoxied the outsides of the tanks and painted them.

I built cradles at frames 5 and 6 to hold the tanks, blocked them to bulkheads at the ends, and used tie-down straps. I made all the connections to the tanks flexible so that a slight movement would not cause stress to the piping or the tanks.

I also spent a lot of time thinking about an engine for the boat. If I had purchased a new one when I started the project, I could have saved a lot of money. By the time I needed the engine, new pollution regulations had come in which seem to have had the effect of driving prices up.

I kept putting off purchasing an engine as long as possible, because of the cost. At first, I left a hole in the main deck through which it could be installed. Then I left a hole in the cabin side so that it could come in that way and be lowered through the hole in the deck. Then, as construction progressed, I closed up the hole in the side and left one in the main cabin roof, thinking that when I finally did get an engine, it could be lowered through the roof by a crane.

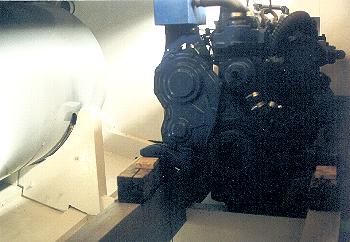

The used six-cylinder Ford diesel cost about one-quarter the cost of a new engine. Note the cylindrical fuel tank at the left. |

Eventually, I came to the point where I had to have an engine. I started looking for a good secondhand one. I bought a six-cylinder Ford diesel engine (Model 2715E) from a lobster fisherman who convinced me that the engine had only been used for lobster fishing and only had 1,500 hours on it. I believed him. The engine was sitting in a shed-not hooked up so it could not be run. He gave me a written warranty for a year. I paid about one-quarter the cost of a new engine.

The sidedecks and cabin sides were planked next. |

I brought the engine home, set it up on blocks, made the necessary connections, and hit the starter. The engine turned over twice, started, and ran perfectly. I cleaned it up, painted it, changed the oil and filters, and made it look like new. I now have it in the boat and have run it about 130 hours with no problems other than to replace a worn hose.