Thunderbolt by Bob Atwater, Seneca, South Carolina

16 November 2010 Update (Cont'd)

Covered the hull with a couple of coats of white primer and

sanded to relive some high points, primarily at the frame

locations. Stopped sanding when the epoxy was reached.

Tired of white primer - - shifted to gray.

Coated the bottom and sides with three coats of Interlux

Royal Blue. I did the rolling with a fine foam roller. My

wife, a reluctant volunteer, followed up using a good quality

3 inch foam brush to quickly tip out the rolled paint.

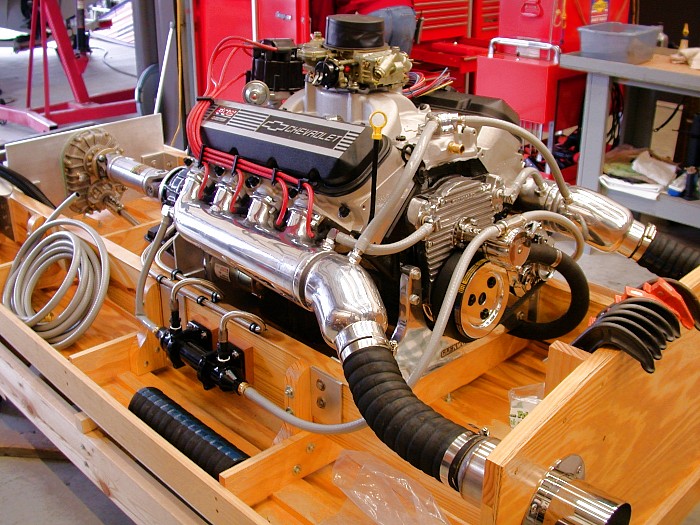

Back to the mockup. The drive train I settled on is a GM 502

cubic inch, 502 hp, big block, performance, crate engine

coupled with a BTE 1.76 racing powerglide transmission and a

22% overdrive Casale V-drive.

The drive shaft was custom made of high tensile strength

aluminum by Denny's in upstate New York. The exhaust

ports were located on the mockup and exhaust hose installed.

After we connected the water lines we actually cranked up the

engine on the mockup. Shortly thereafter, the proprietor

asked my mechanic to move his business elsewhere.

Time to flip the hull. I used a small hole saw and drill to

cut around the cement nails holding the building form and

strong back to the floor. I could not get the nails loose

with the hull overhead. I built a frame of 2 x 4's

slightly wider that the hull at the sheer line. The frame is

bolted and braced to the building form.

Three of us wheeled the hull out of the garage on a set of

wheels attached to the transom end of the building form.

The rope is actually attached to the rails, not the end of

the 2 x 4 frame. Using the opposite side as a skid, the

forklift gently lifted the hull onto its edge supported by

the opposite end of the 2 x 4 frame.

About 16 bags of pine bark mulch covered with old blankets

served as the bed for the hull.

At this point, the hull started to move toward the forklift.

Oops.

The hull was placed on a frame with bunkers adjusted to

accommodate the hull shape. The hull was wheeled in and out

of the garage on the support frame. I preferred to work

outside when conditions allowed. Pictures of the installation

of the front deck, rear deck and dash were lost.