Biscayne 22 by Bob Perkins 2

11. I've read many forum posts from people looking to purchase two 17' x 6" x 1 1/2" beams of Douglas-fir or some other wood to make motor stringers. If you really want a backbone that is straight, true and will never twist or warp, you need to think about laminating your own stringers. Laminations will help prevent the natural tendency for lumber to change shape and you have the added bonus of being able to use less expensive materials found in common lengths.

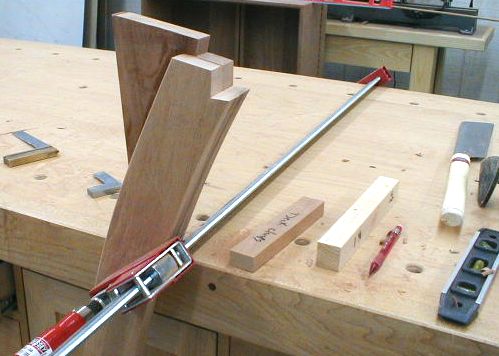

My stringers were made of 3/4" lengths scarfed together, then the two 3/4" planks were laminated to one another. The result is a perfectly straight and stiff backbone for contruction.

12. Here are the sheer clamp and deck clamp notches being precut. They will need custom fitting when installing the parts.

13. I couldn't wait - so while fitting the forward frames, I did a test setup with the stem.

14. I originally presealed the frames with epoxy - If I were to do it again, I would have waited until the hull was together and the decks, etc were in place. It's hard to explain but this step didn't do much at this time.

15. The sub-transom competed. I went all out and used Silicon Bronze fasteners throughout construction.

16. Fitting frame #8 to Stem and geting ready for final attachment.

17. Milestone Reached. All frames, stem and first layer of keel secured permenantly!

18. Inside the frames.

19. Nice Shot with the door open

20. Much like the motor stringers, Laminating the keel also made sense. It adds strength and stiffness. Thirty nine clamps holding the second layer of the keel while the epoxy sets. I could have used a few more.