Biscayne 22 by Bob Perkins 7

61. My first coat of varnish on the transom. I finally figured out the proper way to spray using HVLP. This is so much better than brushing or rolling.

62. Varnishing completed for now - Next turning the hull

63. Tuning day was very hectic and I completely forgot to assign a photographer. Needless to say it went off very well. If you think out all of the logistics ahead of time and have everyone in sync - the turning goes quite simply.

64. View of the left side on the cradle.

65. Right side of boat after flipping the hull

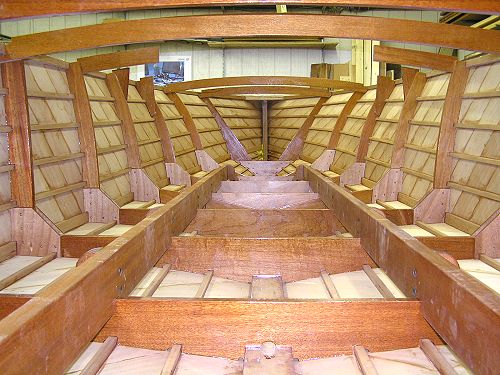

66. Inside the bow view after flipping the hull

67. View of the inside toward the transom

68. Here are the first two laminations of the deck clamp fit and glued into place. There is a bit of effort involved with fairing the sheerline so the deck beams - sheerline and deck clamps all come out proper.

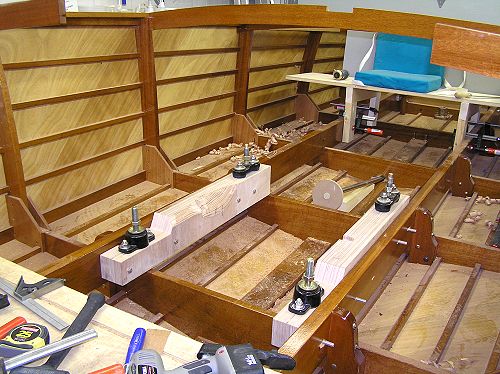

69. Motor Installation: I started by making a rolling cart to work on the motor beds. This came in especially handy just to be able to move the motor around. I went with a Mercruiser 5.7L Mag MPI Horizon 300 HP. I'd sure like to get it on the water - it is a very well designed motor.

70. Each bed is made of laminated ¾ marine plywood and then carved and cut to shape to allow all of the clearances on the motor. The beds are designed to sit on the frames and are bolted to the motor stringers. I was able to preset the motor angle and calibrate it on the cart before putting it into the boat.