Boatbuilding with Plywood

Chapter 6 - Fastenings

Continued

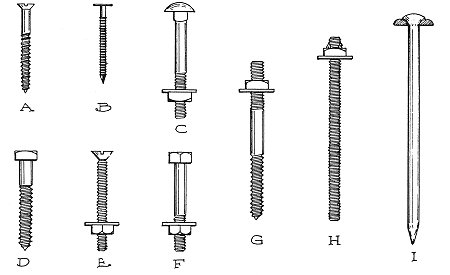

Plate 6A - Fasteners commonly used in plywood boatbuilding include: (A) Flat head wood screw, (B) Ring shank boat nail, and (C) Carriage bolt. Other incidental fastenings may include: (D) Lag bolt, (E) Flat head machine screw, (F) Machine bolt, (G) Hanger bolt, (H) Threaded rod with nut jammed on to form a through-bolt, and (I) Drift with clenched head and ring or washer.

FASTENING MATERIALS

Basically, metal fastenings can be broken down into ferrous (containing iron) and non-ferrous types, which do not contain iron. As most people realize, ferrous metals such as iron and steel will rust when exposed to the elements, and especially so in a salt water environment. Consequently, ordinary steel fastenings have no place in boatbuilding. However, a certain amount of rust and corrosion protection can be given to ordinary steel fastenings by various plating techniques.

One plating technique consists of an electroplating method, which deposits a thin layer of cadmium or zinc onto the metal's surface, and this tends to inhibit the formation of rust to some extent. However, driving such a fastening almost immediately destroys the very thin layer and rust occurs almost as quickly as if the coating didn't exist. These electroplated type screws therefore offer poor rust resistance under salt water or even exposed conditions. Their main advantage is that they won't rust on the hardware dealer's shelf.

A better coating process for steel fastenings is a hot dipped galvanized coating of zinc where the fastenings are immersed in molten zinc thereby depositing a heavy zinc-rich coating onto the fastening. Hot dipped galvanized fastenings do not rust when exposed to the weather, however, they may be subject to galvanic corrosion below the water line in salt water conditions when located adjacent to dissimilar metals.

For a boat that will remain for long periods in salt or brackish waters then, hot dipped galvanized fastenings should not be located side by side with bronze or non-ferrous fastenings or fittings since the less noble metal (in this case, the steel fastenings), will begin to deteriorate. It is possible, however, to use the bronze fastening below the water and the hot dipped galvanized fastening above the waterline. For a trailerable boat or for one that will not remain in salt or brackish waters for long periods, the hot dipped galvanized fastening is entirely suitable, especially for boats covered with fiberglass.

Non-ferrous fastenings for boats usually include brass, bronze, and Monel metals, all of which are copper-based. The brass fastening is often considered corrosion resistant, however, this is not actually the case in a marine salt-water environment. Such a fastening will dezincify, which means that the zinc content will leech out of the fastening causing it to rapidly disintegrate. Besides this, brass fastenings are inherently weak, with the heads of fastenings being easily wrenched off when driven hard or otherwise popping off under stress. Because of these problems, brass fastenings are not recommended, with the possible exception of non-structural joinerywork where strength or corrosion resistance is not important.

Bronze and Monel fastenings are superior fastenings, especially for use below the waterline in boats that will remain in salt or brackish waters. There are many different grades of bronze, however the silicon-type is probably best suited for fastenings. Of course, bronze and Monel fastenings are expensive, but as a total percentage of the cost of the boat, the price is only a small fraction. One must consider also that the extra cost of bronze fastenings will probably be more than repaid by the higher resale value of a bronze fastened boat when it is sold.

Aluminum fastenings are also considered as non-ferrous fastenings, however, since they are weak and not corrosion resistant, they also have no place in plywood boatbuilding for structural use.

Many people are under the impression that stainless steel is an ideal fastening material. While it is true that stainless steel is ordinarily highly rust resistant, it is not totally free from corrosion. When stainless steel is placed under poorly aerated water conditions or otherwise shielded from air, even by having just a thin oil coating, galvanic action can occur, especially when adjacent to dissimilar metals in salt water. This corrosion usually begins as a very small surface pit trapping salt water, which gradually corrodes away to the inner portions of the fastening. Such corrosion is called crevice corrosion and can dissipate a fastening or fitting in the most devious way; from the inside out where it may not be detected until it is too late. The tendency for crevice corrosion to occur will vary depending on the grade of stainless steel. Some grades are more susceptible than others. However, because of the wide array of stainless steel types, and the fact that it is often difficult for the novice to know which type he may be getting, it is usually prudent to avoid stainless steel fastenings for the most part. They are expensive as well.