Glen-L Update

Barry Witt

Editor

|

|

Letter:

Dear Gentlemen,

I thought you might like to see some pictures of the Cracker Box I built from your kit. I finished the boat about 2 years ago but can’t leave it alone, keep changing things as I see boats I like. At present the boat has mahogany sides and decks; the deck is striped with a white seam between planks (like the old Chris-Crafts). The boat’s name is Panache and sports the number P-1. The engine is a converted auto engine; 350 cu. in. Chevy with modifications that generate about 400 hp. The boat goes 78 mph with a 2 blade Menkens steel prop (11 3/4″x17). I hope you like the pictures and the cosmetic changes I have made to your hull.

Sincerely A satisfied customer

Ted Glowa

Burnt Hills, NY

P.S. One of the pictures is of a boat show, while I didn’t win anything in competition against Gar-woods, everybody loved it in the race boat class (replica) and there was some interest due to the relatively low cost to build.

Customers are usually surprised to find that GLEN-L is not a huge company with people scurrying in every direction. In fact GLEN-L is like an extended family. We get together for picnics, talk over our problems …just like any family. In keeping with the do-it-yourself idea, we are our own publisher. We sell only our own designs. All written material from literature to instructions, to the GLEN-L DESIGN BOOK and the other books we publish, are written and prepared for printing at our facilities in Bellflower. We are able to do so much with so few by each of us wearing several hats. When you call in an order, you are usually greeted by Darla or Gayle’s cheerful voice, but if they are busy with the book keeping or processing orders, there’s no telling who you might talk to: Barry in purchasing, Alfredo in shipping, or you might even find themselves talking to one of the designers.

Gentlemen:

I have recently completed building a Double Eagle boat in plywood and fiberglass according to drawings and manuals obtained from you. Enclosed are some photographs taken during the building process and as the boat appears now. I trust that they will be of some interest to you.

It took me almost four years to complete this labor of love and it gave me considerable pleasure. Most of the work was done during the worst and darkest years of civil war that ravaged my country. I took hope and comfort gradually putting it together when bombs and mortars were falling all around. Perhaps it helped to keep sanity and a sense of perspective.

I am proud of my achievement, and as you see I named it “Double Eagle”. I feel that you had a big part to play in it all, and that it is only right and proper that I share it with you.

Kind regards.

Ibrahim Abou Jaoude

Jal Edib, Lebanon

There are two re-occuring questions that we hear from our customers. “Can I put a sail on (name of planing boat)?” and “If I use a larger motor than you recommend (on a displacement boat) can I increase the speed?”

Different hull shapes have advantages for different applications. The ideal characteristics for sailboats, row boats, and eventually low speed power boats have been long understood. These boats need a hull shape that will move easily through the water with a minimum of power. When more power became available, it was found that a new hull form was needed. In order to overcome the limitations of the bow wave, it was necessary to rise out of the water, to plane. On planing hulls, the bottom shape is extremely important to performance, with minor variations causing sometimes dramatic problems. Let’s look at the two basic hull forms to understand why they work the way they do.

Displacement hulls: The overriding fact about displacement boats is that their speed is limited by their length. Speed in knots = 1.34 X square root of the waterline length. The other part of the story is that these hulls are very fuel efficient; they require little power to reach their maximum speed. Attempting to exceed hull speed is guranteed to waste fuel and money and gain little if anything in speed. Row boats and sailboats are most often displacement hulls.

Planing hulls: In theory, a full planing hull (with infinite power) has no speed limit. Our TORNADOS and THUNDERBOLTS regularly exceed 100 mph in competition, with one THUNDERBOLT clocked at 148 mph. Planing boats, when they achieve planing speed, ride on top of the water. They are, however, not properly shaped to be efficient at slow speeds. In our previous Web Letter, we discussed how to re-crisp the trailing edge on a planing boat, but did not explain why.

Why: When a boat is planing, the water flows off the bottom in a sheet and the wave breaks behind the boat. If there is a downturn at the transom (hook), the bow will be driven down, increasing wetted surface and decreasing speed potential. If there is a bottom rise at the transom (rocker), the hull will tend to porpoise (jump out of the water and fall back into the water). If the trailing edge of the bottom at the transom is rounded, the boat will behave as though it has a rocker. This results from water following the radiused bottom, up the transom, sucking the transom down. Speed amplifies these effects, with minor imperfections only causing performance problems at high speed. Having said all this, there are instances when you might want very minor hooks or rockers in the bottom …this is what cavitation plates and trim tabs are for.

Others: Yes Virginia, there are others. There are boats that fit between displacement and planing boats; boats that exceed the speed limitations of displacement boats, but do have higher speed potential of full planing boats. They tend to be less efficient than displacement boats at slow speeds, and less efficient that planing boats at high speed. Their exact characteristics will depend on where their hull form falls between displacement and planing hulls.

Anyway… Is it possible to put a sail on the 13′ FISHERMAN? Ans.: Yes, however, because the FISHERMAN is a planing hull it will be very inefficient (slow) under sail.

If I double the horsepower on the NOYO TRAWLER how much more speed can I get? Ans.: Very little, perhaps a half knot, but your fuel consumption could increase dramatically when the motor runs at full speed.

What do you do if the Bill of Materials for your boat calls out a 1/4″x4’x16′ sheet of plywood? You have two choices: find it, or make it. In the past, long sheets were more readily available than now. If we were to build the boat in our shop, we would use 4’x8′ sheets and join them with a butt block. An alternate method would be to use a scarf joint to join the panels; but in this particular instance, a second joint would be required to make up for the loss in length that occurs when you make a scarf joint. Both of these methods are described on the back of the “How to Use Patterns” sheet that comes with each plans and pattern package.

The “sheer” on our theoretical boat is called out at 1″x1 1/2″x18′ mahogany, and your local lumber yard stocks mahogany only to 12′ long. What do you do… find it or make it. Commonly a scarf joint would be made using the same method as used for scarfing plywood. Another option would be to look for alternate types of wood. The following are commonly used boatbuilding lumbers: cypress, Douglas-fir, long-leaf yellow pine, mahogany (Phillippine-dark red, Honduras, African), white oak, Sitka spruce, and sasafras. In all cases the material should be select material, properly dried.

See our last Web Letter for a discussion of the difference between marine and exterior plywood. Whether exterior can be used depends on the type of boat and where it is used.

Allyn Perry…

See him on our catalog cover with his grandchildren; see him in instructions, our videos, and literature. Allyn is the indispensable man. He was born in Winona, MN. He has two brothers and one sister. His family moved to Southern California in 1954. He learned about GLEN-L by building the STILETTO; in 1971 he started working in the shop.

Allyn has three children and four grandchildren. He plays slow pitch softball and 3 on 3 basketball, coaches girls basketball, enjoys cooking, and is a good and generous friend.

Allyn has almost thirty years of boatbuilding experience and is our resident fiberglassing expert. He is currently building the AMP EATER test model.

Do you have any suppliers of marine plywood or boatbuilding lumber that you can recommend. We would like to expand our list of suppliers…

See the List of Lumber Suppliers on our Web Site.

What, you haven’t heard of scant plywood? Scant is a lumberyard term that means it’s not as thick as the label says. Although some lumberyards are listing the actual size in 1/32’s of an inch. Scant 3/8″ is 11/32″ thick, although it may still be called 3/8″. Obviously the purpose is to get more plywood from a tree. Whenever possible we would prefer full thickness plywood for the planking. We have found, however, that the scant plywood can be used in place of full thickness plywood on many boats without problem. If in doubt on a particular design, check with the designer. When you buy from different sources make sure thicknesses are the same for plywood being butt blocked or scarfed together. We hope this down grading of materials does not continue.

For more information on plywood see the Wood and Plywood Information pages.

Visit the CUSTOMER PHOTOS section…

You could be here or on our design pages,

send us a photo of your Glen-L project.

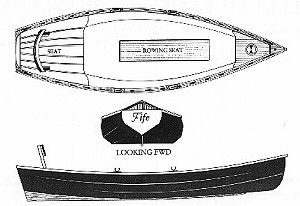

The design criteria for the 12′ FIFE was that it could be carried, easily rowed, support three people, and be stable. FIFE is light weight (the test model weighed only 98 lbs., including fiberglass) with a wide bottom for stability and to maximize bouyancy. The hull depth was kept to 13″ to minimize windage. The rounded sides and tumblehome make this a very stiff boat even using light weight 4mm material on the sides. Most small boats designed for serious rowing tend to feel “tippy”. The wide bottom on the FIFE makes her remarkably stable. People who normally feel unconfortable in small boats will find FIFE comforting. The skeg allows her to row true even with an inexperienced oarsman. Her ample watertight storeage under the fore and aft seats for extra clothing or picnic supplies.

The waterline is at 3″ with a 130 lb. load; 3 1/2″ with 190 lbs., 5″ with 395 lbs., 6″ with 540 lbs. Plenty of capacity for you, a friend, and a hefty picnic basket. With two sets of movable oar lock sockets, the rower’s seat allows the oarsman to change position with different passenger weights or when a passenger sits in the comfortable stern seat. Viewed from aft, she has a traditional “wine glass” stern. The lines guarentee that anywhere FIFE goes, she will get many more than a second glance.

Performance report: An inexperienced oarsman rowed one passenger around the harbor for over 2 1/2 hours without fatigue. There seemed to be little additional effort required with two passengers. With two passengers, the oarsman used the aft oar locks, allowing the forward passenger to sit on the front of the rower’s seat and face forward. The FIFE has been used with an electric trolling motor, with two adults, one 12 volt battery, cruised for an hour and a half, battery still well charged.

Link:

Design page

Fly fishing

Fife by one of the old guys

VOCs or Volatile Organic Compounds are solvents found in most marine paints. These solvents are released into the atmosphere as the paint dries. The lower the VOC content, the lower amount of solvents released into the atmosphere. Because of enviromental concerns, the maximum VOC content in paint has been scaled back over several years. This has meant that paints which were acceptable a few years ago are no longer available. Currently we are selling Interlux Brightside which meets all current VOC requirements. If you would like a color chart and price list, let us know and we will be happy to send you one.

If you are building an inboard boat, one of the power options would be to convert an automotive engine. GLEN-L carries lightweight cast aluminum conversion parts for popular V-8 engines as well as underwater and other hardware needed for installation. Send $2.00 our Inboard Hardware catalog (or request it when ordering our plans), or see Inboard Hardware on-line.

Build more boats

Glen-L boats, of course